ADDRESS

-

Address:

Knight Fire and Security Products Ltd

Unit 84 Seawall Rd Ind Est

Cardiff,

CF24 5TH

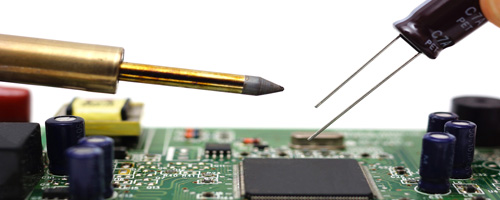

M4EMS has over 20 years experience in conventional Through hole PCB assembly. Technicians produce a wide range of Single and Double sided PCB designs. Assemblies are typically mixed in component type and many designs end up being hybrid assemblies utilising key component attributes and packaging to enhance the design integrity meeting required industry standards. A typical design is made up of Surface mount components on one side of a PCB and Through hole and electromechanical components being placed on the opposite side. This permits maximum processing flexibility and helps protect very small SMT components during through hole processing and product lifecycle. All technicians meet high standards in hand and wave soldering and inspection.

The BLUNDELL CMS400 is a UK built class leading wave soldering machine, it has been the market leader in this country for many years. The machine uses a spray fluxer The spray fluxer allows us to regulate the amount of flux applied to the board to obtain a cleaner PCB after soldering. Using the three stage preheating option, lets us do instant adjustments to the preheat intensity, allowing for PCB's of different thickness and mass to be processed one after the other.

The dual nozzel wave allows us to solder both Through hole Components and SMD Components during the wave solder process.